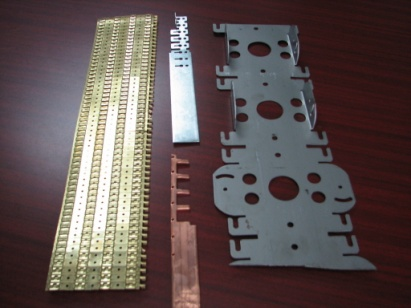

Progressive stamping is a metal working method that incorporates several different stations into a die in order to modify the coiled sheet metal to the specified design. This is done with the aid of an automatic feeding system which feeds the coiled material into a press through the different stations of a progressive die. UMC has the capability to produce progressive tooling with multiple stations such as blanking, punching, bending, forming, piercing, shaving, coining, countersinking, tapping and drawing. This procedure allows UMC to produce parts at a very cost effective price due to multiple operations performed automatically, removing the need for costly secondary operations. Our experienced design engineers and toolmakers create tools that produce parts in tolerance right from the start, thus minimizing waste and saving you money.

For a detailed quotation, or inquiries please email info@umcmfg.com or fax a drawing to 519-622-1152.